High-load linear stage; 2-phase stepper motor; 102 mm travel range; 500 N load capacity; 100 mm/s maximum velocity; ball screw

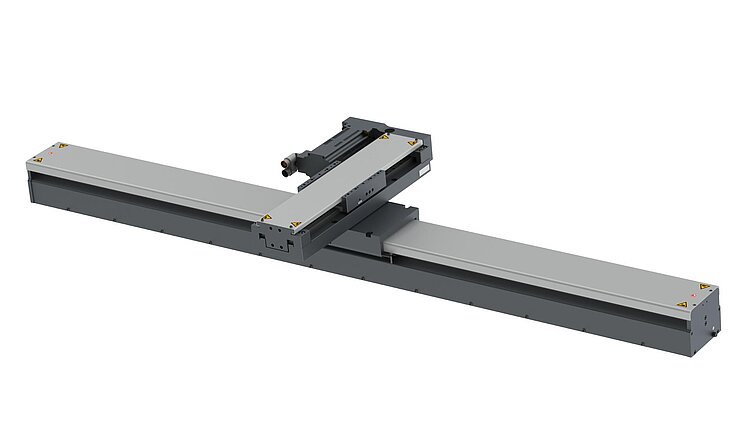

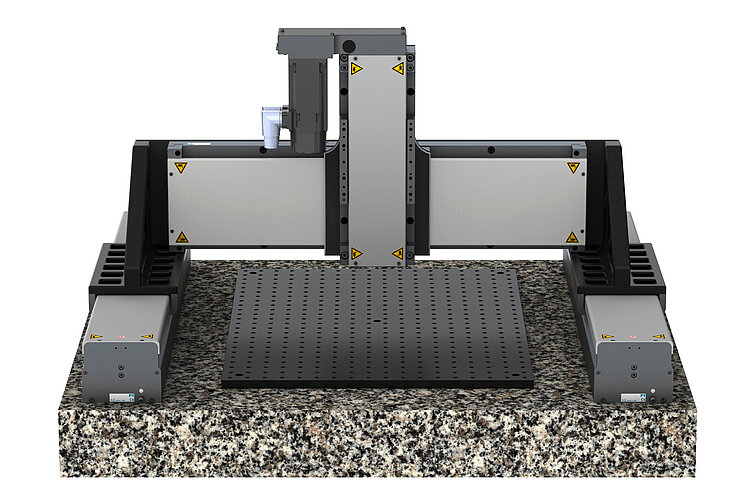

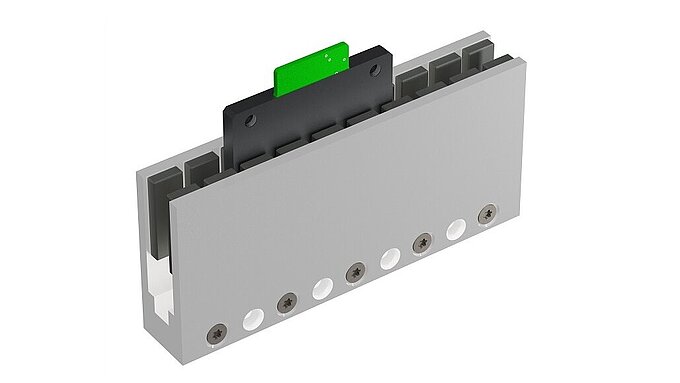

L-812 High-Load Linear Stage

Stepper or Servo Motor • Spindle Drive • Cost Effective

- Width: 114 mm, travel range up to 610 mm

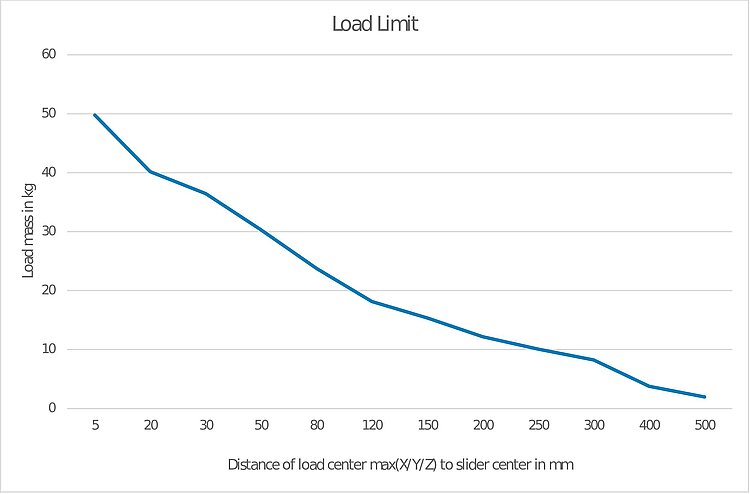

- Precision ball screw, load capacity up to 50 kg

- Stepper or servo motor

- Compact design thanks to models with folded drivetrain

- Models with holding brake for vertical mounting

Powerful linear stage for use in demanding industrial applications

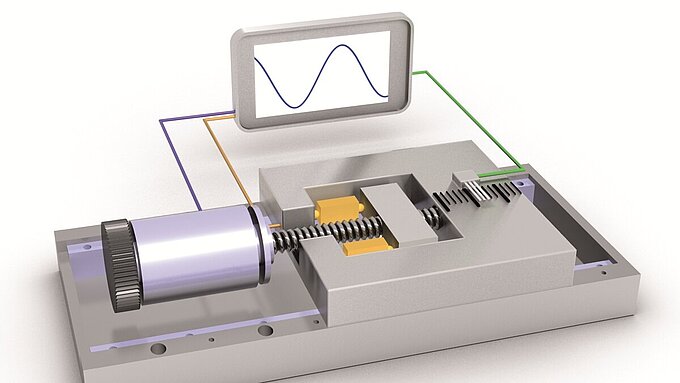

Precision ball screws, high-performance stepper or synchronous servo motors, heavy-duty recirculating ball bearings, and precision rotary encoders enable continuous and reliable operation under high load. The optional holding brake allows the use as Z axis. The ball screw can be relubricated from the outside without disassembling to ensure high reliability and long lifetimes.

Pioneering design

The recirculating ball bearing guides of the L-812 series are designed for high load capacity and dynamics. The high resolution of the motors allows for an improved tracking performance, smaller tracking errors, and faster settling times.

Synchronous servo motor

These motors have high positioning accuracy and high overload capacity over a large rotation speed range. High torque and low inertia ensure the high dynamics of the drives. The long lifetime, high performance, and robustness of these motors allows for excellent results in industrial automation applications.

Stepper motor

Powerful and low-vibration 2-phase stepper motors allow for accurate positioning even without position control.

Options

- Stepper or synchronous servo motor

- Holding brake

- Rotary encoder, incremental or absolute-measuring

- Folded drivetrain for reducing the overall length

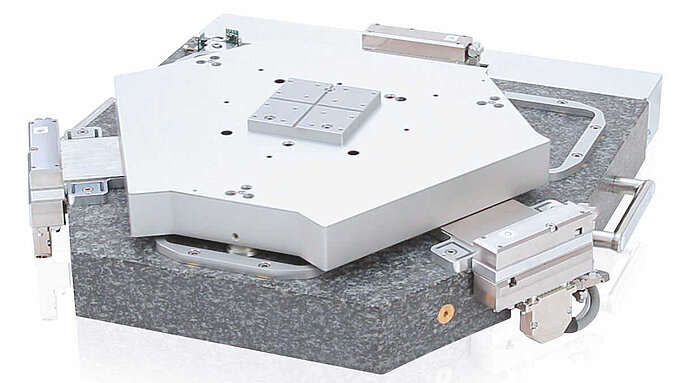

- Optional accessory: L-812.TT1 motion platform

Application fields

- Electronics production: Microassembly, sensor / camera placement

- Laser materials processing: Laser micromachining

- Industrial inkjet printing, matrix plate and printed circuit board production

- Test & inspection

- Manufacturing of medical equipment: Hermetic welding, robotic systems for gene laboratories

Specifications

Specifications

| Motion | L-812.051400 | L-812.051400B | L-812.051400BF | L-812.091400 | L-812.091400B | L-812.091400BF | L-812.171400 | L-812.171400B | L-812.171400BF | L-812.251400 | L-812.251400B | L-812.251400BF | L-812.059432 | L-812.059432B | L-812.059432BF | L-812.099432 | L-812.099432B | L-812.099432BF | L-812.139432 | L-812.179432 | L-812.179432B | L-812.179432BF | L-812.259432 | L-812.259432B | L-812.259432BF | L-812.059453 | L-812.059453B | L-812.059453BF | L-812.099453 | L-812.099453B | L-812.099453BF | L-812.179453 | L-812.179453B | L-812.179453BF | L-812.259453 | L-812.259453B | L-812.259453BF | Tolerance |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Active axes | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | |

| Travel range in X | 102 mm | 102 mm | 102 mm | 204 mm | 204 mm | 204 mm | 407 mm | 407 mm | 407 mm | 610 mm | 610 mm | 610 mm | 102 mm | 102 mm | 102 mm | 204 mm | 204 mm | 204 mm | 304 mm | 407 mm | 407 mm | 407 mm | 610 mm | 610 mm | 610 mm | 102 mm | 102 mm | 102 mm | 204 mm | 204 mm | 204 mm | 407 mm | 407 mm | 407 mm | 610 mm | 610 mm | 610 mm | |

| Acceleration in X, unloaded | 10 m/s² | 10 m/s² | 10 m/s² | 10 m/s² | 10 m/s² | 10 m/s² | 10 m/s² | 10 m/s² | 10 m/s² | 10 m/s² | 10 m/s² | 10 m/s² | 10 m/s² | 10 m/s² | 10 m/s² | 10 m/s² | 10 m/s² | 10 m/s² | 10 m/s² | 10 m/s² | 10 m/s² | 10 m/s² | 10 m/s² | 10 m/s² | 10 m/s² | 10 m/s² | 10 m/s² | 10 m/s² | 10 m/s² | 10 m/s² | 10 m/s² | 10 m/s² | 10 m/s² | 10 m/s² | 10 m/s² | 10 m/s² | 10 m/s² | max. |

| Maximum velocity in X, unloaded | 100 mm/s | 100 mm/s | 100 mm/s | 100 mm/s | 100 mm/s | 100 mm/s | 100 mm/s | 100 mm/s | 100 mm/s | 100 mm/s | 100 mm/s | 100 mm/s | 300 mm/s | 300 mm/s | 300 mm/s | 300 mm/s | 300 mm/s | 300 mm/s | 300 mm/s | 300 mm/s | 300 mm/s | 300 mm/s | 300 mm/s | 300 mm/s | 300 mm/s | 300 mm/s | 300 mm/s | 300 mm/s | 300 mm/s | 300 mm/s | 300 mm/s | 300 mm/s | 300 mm/s | 300 mm/s | 300 mm/s | 300 mm/s | 300 mm/s | |

| Straightness error in Y (straightness) | ± 4 µm | ± 4 µm | ± 4 µm | ± 6 µm | ± 6 µm | ± 6 µm | ± 10 µm | ± 10 µm | ± 10 µm | ± 14 µm | ± 14 µm | ± 14 µm | ± 4 µm | ± 4 µm | ± 4 µm | ± 6 µm | ± 6 µm | ± 6 µm | ± 10 µm | ± 10 µm | ± 10 µm | ± 10 µm | ± 14 µm | ± 14 µm | ± 14 µm | ± 4 µm | ± 4 µm | ± 4 µm | ± 6 µm | ± 6 µm | ± 6 µm | ± 10 µm | ± 10 µm | ± 10 µm | ± 14 µm | ± 14 µm | ± 14 µm | max. |

| Straightness error in Z (flatness) | ± 4 µm | ± 4 µm | ± 4 µm | ± 6 µm | ± 6 µm | ± 6 µm | ± 10 µm | ± 10 µm | ± 10 µm | ± 14 µm | ± 14 µm | ± 14 µm | ± 4 µm | ± 4 µm | ± 4 µm | ± 6 µm | ± 6 µm | ± 6 µm | ± 10 µm | ± 10 µm | ± 10 µm | ± 10 µm | ± 14 µm | ± 14 µm | ± 14 µm | ± 4 µm | ± 4 µm | ± 4 µm | ± 6 µm | ± 6 µm | ± 6 µm | ± 10 µm | ± 10 µm | ± 10 µm | ± 14 µm | ± 14 µm | ± 14 µm | max. |

| Angular error around Y (pitch) | ± 21 µrad | ± 21 µrad | ± 21 µrad | ± 28.5 µrad | ± 28.5 µrad | ± 28.5 µrad | ± 58.5 µrad | ± 58.8 µrad | ± 58.5 µrad | ± 88.5 µrad | ± 88.5 µrad | ± 88.5 µrad | ± 21 µrad | ± 21 µrad | ± 21 µrad | ± 29 µrad | ± 29 µrad | ± 29 µrad | ± 59 µrad | ± 59 µrad | ± 59 µrad | ± 59 µrad | ± 87 µrad | ± 87 µrad | ± 87 µrad | ± 21 µrad | ± 21 µrad | ± 21 µrad | ± 29 µrad | ± 29 µrad | ± 29 µrad | ± 59 µrad | ± 59 µrad | ± 59 µrad | ± 87 µrad | ± 87 µrad | ± 87 µrad | max. |

| Angular error around Z (yaw) | ± 21 µrad | ± 21 µrad | ± 21 µrad | ± 27 µrad | ± 27 µrad | ± 27 µrad | ± 59 µrad | ± 59 µrad | ± 59 µrad | ± 87 µrad | ± 87 µrad | ± 87 µrad | ± 21 µrad | ± 21 µrad | ± 21 µrad | ± 29 µrad | ± 29 µrad | ± 29 µrad | ± 59 µrad | ± 59 µrad | ± 59 µrad | ± 59 µrad | ± 87 µrad | ± 87 µrad | ± 87 µrad | ± 21 µrad | ± 21 µrad | ± 21 µrad | ± 29 µrad | ± 29 µrad | ± 29 µrad | ± 59 µrad | ± 59 µrad | ± 59 µrad | ± 87 µrad | ± 87 µrad | ± 87 µrad | max. |

| Positioning | L-812.051400 | L-812.051400B | L-812.051400BF | L-812.091400 | L-812.091400B | L-812.091400BF | L-812.171400 | L-812.171400B | L-812.171400BF | L-812.251400 | L-812.251400B | L-812.251400BF | L-812.059432 | L-812.059432B | L-812.059432BF | L-812.099432 | L-812.099432B | L-812.099432BF | L-812.139432 | L-812.179432 | L-812.179432B | L-812.179432BF | L-812.259432 | L-812.259432B | L-812.259432BF | L-812.059453 | L-812.059453B | L-812.059453BF | L-812.099453 | L-812.099453B | L-812.099453BF | L-812.179453 | L-812.179453B | L-812.179453BF | L-812.259453 | L-812.259453B | L-812.259453BF | Tolerance |

| Minimum incremental motion in X | 3 µm | 3 µm | 3 µm | 3 µm | 3 µm | 3 µm | 3 µm | 3 µm | 3 µm | 3 µm | 3 µm | 3 µm | 1.5 µm | 1.5 µm | 1.5 µm | 1.5 µm | 1.5 µm | 1.5 µm | 1.5 µm | 1.5 µm | 1.5 µm | 1.5 µm | 1.5 µm | 1.5 µm | 1.5 µm | 1.5 µm | 1.5 µm | 1.5 µm | 1.5 µm | 1.5 µm | 1.5 µm | 1.5 µm | 1.5 µm | 1.5 µm | 1.5 µm | 1.5 µm | 1.5 µm | max. |

| Positioning accuracy in X, uncalibrated | ± 20 µm | ± 20 µm | ± 20 µm | ± 25 µm | ± 25 µm | ± 25 µm | ± 30 µm | ± 30 µm | ± 30 µm | ± 35 µm | ± 35 µm | ± 35 µm | ± 20 µm | ± 20 µm | ± 20 µm | ± 25 µm | ± 25 µm | ± 25 µm | ± 30 µm | ± 30 µm | ± 30 µm | ± 30 µm | ± 35 µm | ± 35 µm | ± 35 µm | ± 20 µm | ± 20 µm | ± 20 µm | ± 25 µm | ± 25 µm | ± 25 µm | ± 30 µm | ± 30 µm | ± 30 µm | ± 35 µm | ± 35 µm | ± 35 µm | max. |

| Bidirectional repeatability in X | 10 µm | 10 µm | 10 µm | 10 µm | 10 µm | 10 µm | 10 µm | 10 µm | 10 µm | 10 µm | 10 µm | 10 µm | 10 µm | 10 µm | 10 µm | 10 µm | 10 µm | 10 µm | 10 µm | 10 µm | 10 µm | 10 µm | 10 µm | 10 µm | 10 µm | 10 µm | 10 µm | 10 µm | 10 µm | 10 µm | 10 µm | 10 µm | 10 µm | 10 µm | 10 µm | 10 µm | 10 µm | max. |

| Limit switches | Inductive, N/C contact,, 5 V, NPN | Inductive, N/C contact,, 5 V, NPN | Inductive, N/C contact,, 5 V, NPN | Inductive, N/C contact,, 5 V, NPN | Inductive, N/C contact,, 5 V, NPN | Inductive, N/C contact,, 5 V, NPN | Inductive, N/C contact,, 5 V, NPN | Inductive, N/C contact,, 5 V, NPN | Inductive, N/C contact,, 5 V, NPN | Inductive, N/C contact,, 5 V, NPN | Inductive, N/C contact,, 5 V, NPN | Inductive, N/C contact,, 5 V, NPN | Inductive, N/C contact,, 5 V, NPN | Inductive, N/C contact,, 5 V, NPN | Inductive, N/C contact,, 5 V, NPN | Inductive, N/C contact,, 5 V, NPN | Inductive, N/C contact,, 5 V, NPN | Inductive, N/C contact,, 5 V, NPN | Inductive, N/C contact,, 5 V, NPN | Inductive, N/C contact,, 5 V, NPN | Inductive, N/C contact,, 5 V, NPN | Inductive, N/C contact,, 5 V, NPN | Inductive, N/C contact,, 5 V, NPN | Inductive, N/C contact,, 5 V, NPN | Inductive, N/C contact,, 5 V, NPN | Inductive, N/C contact,, 5 V, NPN | Inductive, N/C contact,, 5 V, NPN | Inductive, N/C contact,, 5 V, NPN | Inductive, N/C contact,, 5 V, NPN | Inductive, N/C contact,, 5 V, NPN | Inductive, N/C contact,, 5 V, NPN | Inductive, N/C contact,, 5 V, NPN | Inductive, N/C contact,, 5 V, NPN | Inductive, N/C contact,, 5 V, NPN | Inductive, N/C contact,, 5 V, NPN | Inductive, N/C contact,, 5 V, NPN | Inductive, N/C contact,, 5 V, NPN | |

| Integrated sensor | — | — | — | — | — | — | — | — | — | — | — | — | Incremental rotary encoder | Incremental rotary encoder | Incremental rotary encoder | Incremental rotary encoder | Incremental rotary encoder | Incremental rotary encoder | Incremental rotary encoder | Incremental rotary encoder | Incremental rotary encoder | Incremental rotary encoder | Incremental rotary encoder | Incremental rotary encoder | Incremental rotary encoder | Absolute rotary encoder, multi-turn | Absolute rotary encoder, multi-turn | Absolute rotary encoder, multi-turn | Absolute rotary encoder, multi-turn | Absolute rotary encoder, multi-turn | Absolute rotary encoder, multi-turn | Absolute rotary encoder, multi-turn | Absolute rotary encoder, multi-turn | Absolute rotary encoder, multi-turn | Absolute rotary encoder, multi-turn | Absolute rotary encoder, multi-turn | Absolute rotary encoder, multi-turn | |

| Motor encoder: Sensor signal | — | — | — | — | — | — | — | — | — | — | — | — | A/B quadrature, RS-422 | A/B quadrature, RS-422 | A/B quadrature, RS-422 | A/B quadrature, RS-422 | A/B quadrature, RS-422 | A/B quadrature, RS-422 | A/B quadrature, RS-422 | A/B quadrature, RS-422 | A/B quadrature, RS-422 | A/B quadrature, RS-422 | A/B quadrature, RS-422 | A/B quadrature, RS-422 | A/B quadrature, RS-422 | BiSS-C | BiSS-C | BiSS-C | BiSS-C | BiSS-C | BiSS-C | BiSS-C | BiSS-C | BiSS-C | BiSS-C | BiSS-C | BiSS-C | |

| Resolution, motor encoder | — | — | — | — | — | — | — | — | — | — | — | — | 10000 Cts./rev. | 10000 Cts./rev. | 10000 Cts./rev. | 10000 Cts./rev. | 10000 Cts./rev. | 10000 Cts./rev. | 10000 Cts./rev. | 10000 Cts./rev. | 10000 Cts./rev. | 10000 Cts./rev. | 10000 Cts./rev. | 10000 Cts./rev. | 10000 Cts./rev. | — | — | — | — | — | — | — | — | — | — | — | — | |

| Resolution, motor encoder, bit width | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 24 bit | 24 bit | 24 bit | 24 bit | 24 bit | 24 bit | 24 bit | 24 bit | 24 bit | 24 bit | 24 bit | 24 bit | |

| Number of revolutions, motor encoder, bit width | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | 12 bit | 12 bit | 12 bit | 12 bit | 12 bit | 12 bit | 12 bit | 12 bit | 12 bit | 12 bit | 12 bit | 12 bit | |

| Drive Properties | L-812.051400 | L-812.051400B | L-812.051400BF | L-812.091400 | L-812.091400B | L-812.091400BF | L-812.171400 | L-812.171400B | L-812.171400BF | L-812.251400 | L-812.251400B | L-812.251400BF | L-812.059432 | L-812.059432B | L-812.059432BF | L-812.099432 | L-812.099432B | L-812.099432BF | L-812.139432 | L-812.179432 | L-812.179432B | L-812.179432BF | L-812.259432 | L-812.259432B | L-812.259432BF | L-812.059453 | L-812.059453B | L-812.059453BF | L-812.099453 | L-812.099453B | L-812.099453BF | L-812.179453 | L-812.179453B | L-812.179453BF | L-812.259453 | L-812.259453B | L-812.259453BF | Tolerance |

| Drive type | 2-phase stepper motor | 2-phase stepper motor | 2-phase stepper motor | 2-phase stepper motor | 2-phase stepper motor | 2-phase stepper motor | 2-phase stepper motor | 2-phase stepper motor | 2-phase stepper motor | 2-phase stepper motor | 2-phase stepper motor | 2-phase stepper motor | Synchronous servo motor | Synchronous servo motor | Synchronous servo motor | Synchronous servo motor | Synchronous servo motor | Synchronous servo motor | Synchronous servo motor | Synchronous servo motor | Synchronous servo motor | Synchronous servo motor | Synchronous servo motor | Synchronous servo motor | Synchronous servo motor | Synchronous servo motor | Synchronous servo motor | Synchronous servo motor | Synchronous servo motor | Synchronous servo motor | Synchronous servo motor | Synchronous servo motor | Synchronous servo motor | Synchronous servo motor | Synchronous servo motor | Synchronous servo motor | Synchronous servo motor | |

| Nominal voltage | 48 V | 48 V | 48 V | 48 V | 48 V | 48 V | 48 V | 48 V | 48 V | 48 V | 48 V | 48 V | 310 V | 310 V | 310 V | 310 V | 310 V | 310 V | 310 V | 310 V | 310 V | 310 V | 310 V | 310 V | 310 V | 310 V | 310 V | 310 V | 310 V | 310 V | 310 V | 310 V | 310 V | 310 V | 310 V | 310 V | 310 V | |

| Nominal current, RMS | 4.2 A | 4.2 A | 4.2 A | 4.2 A | 4.2 A | 4.2 A | 4.2 A | 4.2 A | 4.2 A | 4.2 A | 4.2 A | 4.2 A | 1.5 A | 1.5 A | 1.5 A | 1.5 A | 1.5 A | 1.5 A | 1.5 A | 1.5 A | 1.5 A | 1.5 A | 1.5 A | 1.5 A | 1.5 A | 1.5 A | 1.5 A | 1.5 A | 1.5 A | 1.5 A | 1.5 A | 1.5 A | 1.5 A | 1.5 A | 1.5 A | 1.5 A | 1.5 A | typ. |

| Peak current, RMS | 4.2 A | 4.2 A | 4.2 A | 4.2 A | 4.2 A | 4.2 A | 4.2 A | 4.2 A | 4.2 A | 4.2 A | 4.2 A | 4.2 A | 4.5 A | 4.5 A | 4.5 A | 4.5 A | 4.5 A | 4.5 A | 4.5 A | 4.5 A | 4.5 A | 4.5 A | 4.5 A | 4.5 A | 4.5 A | 4.5 A | 4.5 A | 4.5 A | 4.5 A | 4.5 A | 4.5 A | 4.5 A | 4.5 A | 4.5 A | 4.5 A | 4.5 A | 4.5 A | typ. |

| Maximum power consumption | 10 W | 10 W | 10 W | 10 W | 10 W | 10 W | 10 W | 10 W | 10 W | 10 W | 10 W | 10 W | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | |

| Motor resolution | 200 Full steps/rev. | 200 Full steps/rev. | 200 Full steps/rev. | 200 Full steps/rev. | 200 Full steps/rev. | 200 Full steps/rev. | 200 Full steps/rev. | 200 Full steps/rev. | 200 Full steps/rev. | 200 Full steps/rev. | 200 Full steps/rev. | 200 Full steps/rev. | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | — | |

| Drive force in X | 377 N | 377 N | 377 N | 377 N | 377 N | 377 N | 377 N | 377 N | 377 N | 377 N | 377 N | 377 N | 800 N | 800 N | 800 N | 800 N | 800 N | 800 N | 800 N | 800 N | 800 N | 800 N | 800 N | 800 N | 800 N | 800 N | 800 N | 800 N | 800 N | 800 N | 800 N | 800 N | 800 N | 800 N | 800 N | 800 N | 800 N | typ. |

| Torque constant | — | — | — | — | — | — | — | — | — | — | — | — | 0.43 N·m/A | 0.43 N·m/A | 0.43 N·m/A | 0.43 N·m/A | 0.43 N·m/A | 0.43 N·m/A | 0.43 N·m/A | 0.43 N·m/A | 0.43 N·m/A | 0.43 N·m/A | 0.43 N·m/A | 0.43 N·m/A | 0.43 N·m/A | 0.43 N·m/A | 0.43 N·m/A | 0.43 N·m/A | 0.43 N·m/A | 0.43 N·m/A | 0.43 N·m/A | 0.43 N·m/A | 0.43 N·m/A | 0.43 N·m/A | 0.43 N·m/A | 0.43 N·m/A | 0.43 N·m/A | typ. |

| Resistance phase-phase | 0.5 Ω | 0.5 Ω | 0.5 Ω | 0.5 Ω | 0.5 Ω | 0.5 Ω | 0.5 Ω | 0.5 Ω | 0.5 Ω | 0.5 Ω | 0.5 Ω | 0.5 Ω | 10.1 Ω | 10.1 Ω | 10.1 Ω | 10.1 Ω | 10.1 Ω | 10.1 Ω | 10.1 Ω | 10.1 Ω | 10.1 Ω | 10.1 Ω | 10.1 Ω | 10.1 Ω | 10.1 Ω | 10.1 Ω | 10.1 Ω | 10.1 Ω | 10.1 Ω | 10.1 Ω | 10.1 Ω | 10.1 Ω | 10.1 Ω | 10.1 Ω | 10.1 Ω | 10.1 Ω | 10.1 Ω | typ. |

| Inductance phase-phase | 1.2 mH | 1.2 mH | 1.2 mH | 1.2 mH | 1.2 mH | 1.2 mH | 1.2 mH | 1.2 mH | 1.2 mH | 1.2 mH | 1.2 mH | 1.2 mH | 17.5 mH | 17.5 mH | 17.5 mH | 17.5 mH | 17.5 mH | 17.5 mH | 17.5 mH | 17.5 mH | 17.5 mH | 17.5 mH | 17.5 mH | 17.5 mH | 17.5 mH | 17.5 mH | 17.5 mH | 17.5 mH | 17.5 mH | 17.5 mH | 17.5 mH | 17.5 mH | 17.5 mH | 17.5 mH | 17.5 mH | 17.5 mH | 17.5 mH | |

| Back EMF, phase-phase, rotational | — | — | — | — | — | — | — | — | — | — | — | — | 14.5 V/kRPM | 14.5 V/kRPM | 14.5 V/kRPM | 14.5 V/kRPM | 14.5 V/kRPM | 14.5 V/kRPM | 14.5 V/kRPM | 14.5 V/kRPM | 14.5 V/kRPM | 14.5 V/kRPM | 14.5 V/kRPM | 14.5 V/kRPM | 14.5 V/kRPM | 14.5 V/kRPM | 14.5 V/kRPM | 14.5 V/kRPM | 14.5 V/kRPM | 14.5 V/kRPM | 14.5 V/kRPM | 14.5 V/kRPM | 14.5 V/kRPM | 14.5 V/kRPM | 14.5 V/kRPM | 14.5 V/kRPM | 14.5 V/kRPM | max. |

| Number of pole pairs | — | — | — | — | — | — | — | — | — | — | — | — | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | |

| Mechanical Properties | L-812.051400 | L-812.051400B | L-812.051400BF | L-812.091400 | L-812.091400B | L-812.091400BF | L-812.171400 | L-812.171400B | L-812.171400BF | L-812.251400 | L-812.251400B | L-812.251400BF | L-812.059432 | L-812.059432B | L-812.059432BF | L-812.099432 | L-812.099432B | L-812.099432BF | L-812.139432 | L-812.179432 | L-812.179432B | L-812.179432BF | L-812.259432 | L-812.259432B | L-812.259432BF | L-812.059453 | L-812.059453B | L-812.059453BF | L-812.099453 | L-812.099453B | L-812.099453BF | L-812.179453 | L-812.179453B | L-812.179453BF | L-812.259453 | L-812.259453B | L-812.259453BF | Tolerance |

| Permissible push force in Y | 250 N | 250 N | 250 N | 250 N | 250 N | 250 N | 250 N | 250 N | 250 N | 250 N | 250 N | 250 N | 250 N | 250 N | 250 N | 250 N | 250 N | 250 N | 250 N | 250 N | 250 N | 250 N | 250 N | 250 N | 250 N | 250 N | 250 N | 250 N | 250 N | 250 N | 250 N | 250 N | 250 N | 250 N | 250 N | 250 N | 250 N | max. |

| Permissible push force in Z | 500 N | 500 N | 500 N | 500 N | 500 N | 500 N | 500 N | 500 N | 500 N | 500 N | 500 N | 500 N | 500 N | 500 N | 500 N | 500 N | 500 N | 500 N | 500 N | 500 N | 500 N | 500 N | 500 N | 500 N | 500 N | 500 N | 500 N | 500 N | 500 N | 500 N | 500 N | 500 N | 500 N | 500 N | 500 N | 500 N | 500 N | max. |

| Holding force in X, passive | — | 500 N | 500 N | — | 500 N | 500 N | — | 500 N | 500 N | — | 500 N | 500 N | — | 500 N | 500 N | — | 500 N | 500 N | — | — | 500 N | 500 N | — | 500 N | 500 N | — | 500 N | 500 N | — | 500 N | 500 N | — | 500 N | 500 N | — | 500 N | 500 N | |

| Moved mass in X, unloaded | 2800 g | 2800 g | 2800 g | 2800 g | 2800 g | 2800 g | 2800 g | 2800 g | 2800 g | 2800 g | 2800 g | 2800 g | 2800 g | 2800 g | 2800 g | 2800 g | 2800 g | 2800 g | 2800 g | 2800 g | 2800 g | 2800 g | 2800 g | 2800 g | 2800 g | 2800 g | 2800 g | 2800 g | 2800 g | 2800 g | 2800 g | 2800 g | 2800 g | 2800 g | 2800 g | 2800 g | 2800 g | |

| Drive screw type | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | Ball screw | |

| Drive screw pitch | 5 mm | 5 mm | 5 mm | 5 mm | 5 mm | 5 mm | 5 mm | 5 mm | 5 mm | 5 mm | 5 mm | 5 mm | 5 mm | 5 mm | 5 mm | 5 mm | 5 mm | 5 mm | 5 mm | 5 mm | 5 mm | 5 mm | 5 mm | 5 mm | 5 mm | 5 mm | 5 mm | 5 mm | 5 mm | 5 mm | 5 mm | 5 mm | 5 mm | 5 mm | 5 mm | 5 mm | 5 mm | |

| Guide | Recirculating ball bearing guide | Recirculating ball bearing guide | Recirculating ball bearing guide | Recirculating ball bearing guide | Recirculating ball bearing guide | Recirculating ball bearing guide | Recirculating ball bearing guide | Recirculating ball bearing guide | Recirculating ball bearing guide | Recirculating ball bearing guide | Recirculating ball bearing guide | Recirculating ball bearing guide | Recirculating ball bearing guide | Recirculating ball bearing guide | Recirculating ball bearing guide | Recirculating ball bearing guide | Recirculating ball bearing guide | Recirculating ball bearing guide | Recirculating ball bearing guide | Recirculating ball bearing guide | Recirculating ball bearing guide | Recirculating ball bearing guide | Recirculating ball bearing guide | Recirculating ball bearing guide | Recirculating ball bearing guide | Recirculating ball bearing guide | Recirculating ball bearing guide | Recirculating ball bearing guide | Recirculating ball bearing guide | Recirculating ball bearing guide | Recirculating ball bearing guide | Recirculating ball bearing guide | Recirculating ball bearing guide | Recirculating ball bearing guide | Recirculating ball bearing guide | Recirculating ball bearing guide | Recirculating ball bearing guide | |

| Overall mass | 6800 g | 6900 g | 7000 g | 7800 g | 7900 g | 8000 g | 9900 g | 10000 g | 10100 g | 11900 g | 12000 g | 12100 g | 7300 g | 7400 g | 7500 g | 8300 g | 8400 g | 8500 g | 10400 g | 10400 g | 10500 g | 10600 g | 12500 g | 12600 g | 12700 g | 7300 g | 7400 g | 7500 g | 8300 g | 8400 g | 8500 g | 10400 g | 10500 g | 10600 g | 12500 g | 12600 g | 12700 g | |

| Material | Aluminum, black anodized; stainless steel | Aluminum, black anodized; stainless steel | Aluminum, black anodized; stainless steel | Aluminum, black anodized; stainless steel | Aluminum, black anodized; stainless steel | Aluminum, black anodized; stainless steel | Aluminum, black anodized; stainless steel | Aluminum, black anodized; stainless steel | Aluminum, black anodized; stainless steel | Aluminum, black anodized; stainless steel | Aluminum, black anodized; stainless steel | Aluminum, black anodized; stainless steel | Aluminum, black anodized; stainless steel | Aluminum, black anodized; stainless steel | Aluminum, black anodized; stainless steel | Aluminum, black anodized; stainless steel | Aluminum, black anodized; stainless steel | Aluminum, black anodized; stainless steel | Aluminum, black anodized; stainless steel | Aluminum, black anodized; stainless steel | Aluminum, black anodized; stainless steel | Aluminum, black anodized; stainless steel | Aluminum, black anodized; stainless steel | Aluminum, black anodized; stainless steel | Aluminum, black anodized; stainless steel | Aluminum, black anodized; stainless steel | Aluminum, black anodized; stainless steel | Aluminum, black anodized; stainless steel | Aluminum, black anodized; stainless steel | Aluminum, black anodized; stainless steel | Aluminum, black anodized; stainless steel | Aluminum, black anodized; stainless steel | Aluminum, black anodized; stainless steel | Aluminum, black anodized; stainless steel | Aluminum, black anodized; stainless steel | Aluminum, black anodized; stainless steel | Aluminum, black anodized; stainless steel | |

| Holding brake | — | Electromagnetic holding brake | Electromagnetic holding brake | — | Electromagnetic holding brake | Electromagnetic holding brake | — | Electromagnetic holding brake | Electromagnetic holding brake | — | Electromagnetic holding brake | Electromagnetic holding brake | — | Electromagnetic holding brake | Electromagnetic holding brake | — | Electromagnetic holding brake | Electromagnetic holding brake | — | — | Electromagnetic holding brake | Electromagnetic holding brake | — | Electromagnetic holding brake | Electromagnetic holding brake | — | Electromagnetic holding brake | Electromagnetic holding brake | — | Electromagnetic holding brake | Electromagnetic holding brake | — | Electromagnetic holding brake | Electromagnetic holding brake | — | Electromagnetic holding brake | Electromagnetic holding brake | |

| Miscellaneous | L-812.051400 | L-812.051400B | L-812.051400BF | L-812.091400 | L-812.091400B | L-812.091400BF | L-812.171400 | L-812.171400B | L-812.171400BF | L-812.251400 | L-812.251400B | L-812.251400BF | L-812.059432 | L-812.059432B | L-812.059432BF | L-812.099432 | L-812.099432B | L-812.099432BF | L-812.139432 | L-812.179432 | L-812.179432B | L-812.179432BF | L-812.259432 | L-812.259432B | L-812.259432BF | L-812.059453 | L-812.059453B | L-812.059453BF | L-812.099453 | L-812.099453B | L-812.099453BF | L-812.179453 | L-812.179453B | L-812.179453BF | L-812.259453 | L-812.259453B | L-812.259453BF | Tolerance |

| Operating temperature range | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | |

| Connector | HD D-sub 26 (m) | HD D-sub 26 (m) | HD D-sub 26 (m) | HD D-sub 26 (m) | HD D-sub 26 (m) | HD D-sub 26 (m) | HD D-sub 26 (m) | HD D-sub 26 (m) | HD D-sub 26 (m) | HD D-sub 26 (m) | HD D-sub 26 (m) | HD D-sub 26 (m) | M15 9-pole (m) | M15 9-pole (m) | M15 9-pole (m) | M15 9-pole (m) | M15 9-pole (m) | M15 9-pole (m) | M15 9-pole (m) | M15 9-pole (m) | M15 9-pole (m) | M15 9-pole (m) | M15 9-pole (m) | M15 9-pole (m) | M15 9-pole (m) | M15 9-pole (m) | M15 9-pole (m) | M15 9-pole (m) | M15 9-pole (m) | M15 9-pole (m) | M15 9-pole (m) | M15 9-pole (m) | M15 9-pole (m) | M15 9-pole (m) | M15 9-pole (m) | M15 9-pole (m) | M15 9-pole (m) | |

| Connector for motor encoder | — | — | — | — | — | — | — | — | — | — | — | — | M15 15-pole (m) | M15 15-pole (m) | M15 15-pole (m) | M15 15-pole (m) | M15 15-pole (m) | M15 15-pole (m) | M15 15-pole (m) | M15 15-pole (m) | M15 15-pole (m) | M15 15-pole (m) | M15 15-pole (m) | M15 15-pole (m) | M15 15-pole (m) | M15 15-pole (m) | M15 15-pole (m) | M15 15-pole (m) | M15 15-pole (m) | M15 15-pole (m) | M15 15-pole (m) | M15 15-pole (m) | M15 15-pole (m) | M15 15-pole (m) | M15 15-pole (m) | M15 15-pole (m) | M15 15-pole (m) | |

| Grease nipple of drive screw | M6 | M6 | M6 | M6 | M6 | M6 | M6 | M6 | M6 | M6 | M6 | M6 | M6 | M6 | M6 | M6 | M6 | M6 | M6 | M6 | M6 | M6 | M6 | M6 | M6 | M6 | M6 | M6 | M6 | M6 | M6 | M6 | M6 | M6 | M6 | M6 | M6 | |

| Recommended controllers / drivers | C-663 G-901 G-910 ACS modular controller | C-663 G-901 G-910 ACS modular controller | C-663 G-901 G-910 ACS modular controller | C-663 G-901 G-910 ACS modular controller | C-663 G-901 G-910 ACS modular controller | C-663 G-901 G-910 ACS modular controller | C-663 G-901 G-910 ACS modular controller | C-663 G-901 G-910 ACS modular controller | C-663 G-901 G-910 ACS modular controller | C-663 G-901 G-910 ACS modular controller | C-663 G-901 G-910 ACS modular controller | C-663 G-901 G-910 ACS modular controller | G-901 G-910 ACS modular controller | G-901 G-910 ACS modular controller | G-901 G-910 ACS modular controller | G-901 G-910 ACS modular controller | G-901 G-910 ACS modular controller | G-901 G-910 ACS modular controller | G-901 G-910 ACS modular controller | G-901 G-910 ACS modular controller | G-901 G-910 ACS modular controller | G-901 G-910 ACS modular controller | G-901 G-910 ACS modular controller | G-901 G-910 ACS modular controller | G-901 G-910 ACS modular controller | G-901 G-910 ACS modular controller | G-901 G-910 ACS modular controller | G-901 G-910 ACS modular controller | G-901 G-910 ACS modular controller | G-901 G-910 ACS modular controller | G-901 G-910 ACS modular controller | G-901 G-910 ACS modular controller | G-901 G-910 ACS modular controller | G-901 G-910 ACS modular controller | G-901 G-910 ACS modular controller | G-901 G-910 ACS modular controller | G-901 G-910 ACS modular controller |

Note regarding the maximum velocity of the L-812.xx1400B / L-812.xx1400BF: When vertically mounted: 40 mm/s.

Note regarding the maximum velocity for L-812.xx94xx[B|BF]: A controller with 320 V DC intermediate voltage is necessary for reaching the maximum velocity. With this intermediate voltage the maximum velocity is reached both in an unloaded state and when fully loaded (50kg).

Note regarding the design resolution of the L-812.xx1400[B|BF]: Value valid for full-step mode (full steps of 1.8°)

Note regarding the moved mass: With L-812.TT1 platform: 3.4 kg.

Note regarding the permissible push force in Z for L-812.xxxxxxB / L-812.xxxxxxBF: When vertically mounted: 300 N.

For more information on the torques permitted for loading the L-812, see the diagram of load limits

Technical data is specified on a granite table with a flatness of ±2µm.

At PI, technical data is specified at 22 ±3 °C. Unless otherwise stated, the values are for unloaded conditions. Some properties are interdependent. The designation "typ." indicates a statistical average for a property; it does not indicate a guaranteed value for every product supplied. During the final inspection of a product, only selected properties are analyzed, not all. Please note that some product characteristics may deteriorate with increasing operating time.

Downloads

Datasheet

Documentation

User Manual L812UM0002

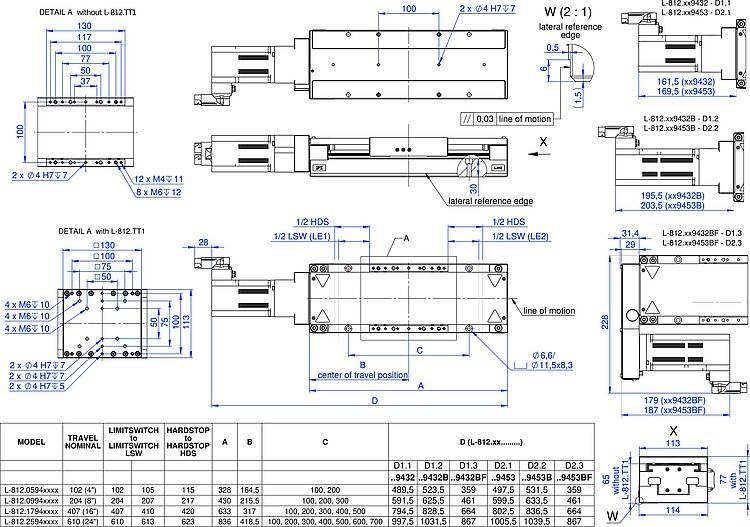

L-812.xx9432 High-Load Linear Stage

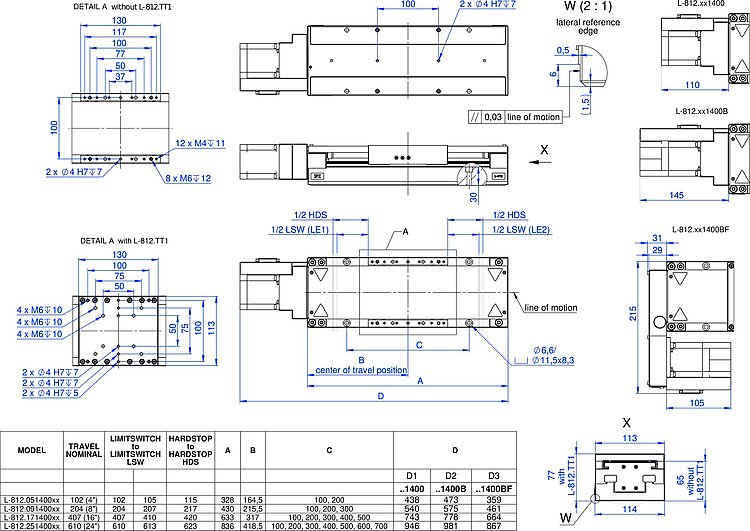

User Manual L812UM0001

L-812.xx1400 Linear Stage with Stepper Motor

User Manual L812UM0003

L-812.xx9453 High-Load Linear Stage

3D Models

3-D model L-812.xx9432B

3-D model L-812.xx9453BF

3-D model L-812.xx9432BF

3-D model L-812.xx1400BF

3-D model L-812.xx1400B

3-D model L-812.xx1400

3-D model L-812.xx9453B

3-D model L-812.xx9453

3-D model L-812.xx9432

Ask for a free quote on quantities required, prices, and lead times or describe your desired modification.

High-load linear stage; 2-phase stepper motor; 102 mm travel range; 500 N load capacity; 100 mm/s maximum velocity; ball screw; electromagnetic holding brake

High-load linear stage; 2-phase stepper motor; 102 mm travel range; 500 N load capacity; 100 mm/s maximum velocity; ball screw; electromagnetic holding brake; folded drivetrain

High-load linear stage; 2-phase stepper motor; 204 mm travel range; 500 N load capacity; 100 mm/s maximum velocity; ball screw

High-load linear stage; 2-phase stepper motor; 204 mm travel range; 500 N load capacity; 100 mm/s maximum velocity; ball screw; electromagnetic holding brake

High-load linear stage; 2-phase stepper motor; 204 mm travel range; 500 N load capacity; 100 mm/s maximum velocity; ball screw; electromagnetic holding brake; folded drivetrain

High-load linear stage; 2-phase stepper motor; 407 mm travel range; 500 N load capacity; 100 mm/s maximum velocity; ball screw

High-load linear stage; 2-phase stepper motor; 407 mm travel range; 500 N load capacity; 100 mm/s maximum velocity; ball screw; electromagnetic holding brake

High-load linear stage; 2-phase stepper motor; 407 mm travel range; 500 N load capacity; 100 mm/s maximum velocity; ball screw; electromagnetic holding brake; folded drivetrain

High-load linear stage; 2-phase stepper motor; 610 mm travel range; 500 N load capacity; 100 mm/s maximum velocity; ball screw

High-load linear stage; 2-phase stepper motor; 610 mm travel range; 500 N load capacity; 100 mm/s maximum velocity; ball screw; electromagnetic holding brake

High-load linear stage; 2-phase stepper motor; 610 mm travel range; 500 N load capacity; 100 mm/s maximum velocity; ball screw; electromagnetic holding brake; folded drivetrain

High-load linear stage; synchronous servo motor to 310 V; 102 mm travel range; 500 N load capacity; 300 mm/s maximum velocity; ball screw; incremental rotary encoder

High-load linear stage; synchronous servo motor to 310 V; 102 mm travel range; 500 N load capacity; 300 mm/s maximum velocity; ball screw; incremental rotary encoder; electromagnetic holding brake

High-load linear stage; synchronous servo motor to 310 V; 102 mm travel range; 500 N load capacity; 300 mm/s maximum velocity; ball screw; incremental rotary encoder; electromagnetic holding brake; folded drivetrain

High-load linear stage; synchronous servo motor to 310 V; 204 mm travel range; 500 N load capacity; 300 mm/s maximum velocity; ball screw; incremental rotary encoder

High-load linear stage; synchronous servo motor to 310 V; 204 mm travel range; 500 N load capacity; 300 mm/s maximum velocity; ball screw; incremental rotary encoder; electromagnetic holding brake

High-load linear stage; synchronous servo motor to 310 V; 204 mm travel range; 500 N load capacity; 300 mm/s maximum velocity; ball screw; incremental rotary encoder; electromagnetic holding brake; folded drivetrain

High-load linear stage; synchronous servo motor to 310 V; 304 mm travel range; 500 N load capacity; 300 mm/s maximum velocity; ball screw; incremental rotary encoder

High-load linear stage; synchronous servo motor to 310 V; 407 mm travel range; 500 N load capacity; 300 mm/s maximum velocity; ball screw; incremental rotary encoder

High-load linear stage; synchronous servo motor to 310 V; 407 mm travel range; 500 N load capacity; 300 mm/s maximum velocity; ball screw; incremental rotary encoder; electromagnetic holding brake

High-load linear stage; synchronous servo motor to 310 V; 407 mm travel range; 500 N load capacity; 300 mm/s maximum velocity; ball screw; incremental rotary encoder; electromagnetic holding brake; folded drivetrain

High-load linear stage; synchronous servo motor to 310 V; 610 mm travel range; 500 N load capacity; 300 mm/s maximum velocity; ball screw; incremental rotary encoder

High-load linear stage; synchronous servo motor to 310 V; 610 mm travel range; 500 N load capacity; 300 mm/s maximum velocity; ball screw; incremental rotary encoder; electromagnetic holding brake

High-load linear stage; synchronous servo motor to 310 V; 610 mm travel range; 500 N load capacity; 300 mm/s maximum velocity; ball screw; incremental rotary encoder; electromagnetic holding brake; folded drivetrain

High-load linear stage; synchronous servo motor to 310 V; 102 mm travel range; 500 N load capacity; 300 mm/s maximum velocity; ball screw; absolute rotary encoder, multiturn

High-load linear stage; synchronous servo motor to 310 V; 102 mm travel range; 500 N load capacity; 300 mm/s maximum velocity; ball screw; absolute rotary encoder, multiturn; electromagnetic holding brake

High-load linear stage; synchronous servo motor to 310 V; 102 mm travel range; 500 N load capacity; 300 mm/s maximum velocity; ball screw; absolute rotary encoder, multiturn; electromagnetic holding brake; folded drivetrain

High-load linear stage; synchronous servo motor to 310 V; 204 mm travel range; 500 N load capacity; 300 mm/s maximum velocity; ball screw; absolute rotary encoder, multiturn

High-load linear stage; synchronous servo motor to 310 V; 204 mm travel range; 500 N load capacity; 300 mm/s maximum velocity; ball screw; absolute rotary encoder, multiturn; electromagnetic holding brake

High-load linear stage; synchronous servo motor to 310 V; 204 mm travel range; 500 N load capacity; 300 mm/s maximum velocity; ball screw; absolute rotary encoder, multiturn; electromagnetic holding brake; folded drivetrain

High-load linear stage; synchronous servo motor to 310 V; 407 mm travel range; 500 N load capacity; 300 mm/s maximum velocity; ball screw; absolute rotary encoder, multiturn

High-load linear stage; synchronous servo motor to 310 V; 407 mm travel range; 500 N load capacity; 300 mm/s maximum velocity; ball screw; absolute rotary encoder, multiturn; electromagnetic holding brake

High-load linear stage; synchronous servo motor to 310 V; 407 mm travel range; 500 N load capacity; 300 mm/s maximum velocity; ball screw; absolute rotary encoder, multiturn; electromagnetic holding brake; folded drivetrain

High-load linear stage; synchronous servo motor to 310 V; 610 mm travel range; 500 N load capacity; 300 mm/s maximum velocity; ball screw; absolute rotary encoder, multiturn

High-load linear stage; synchronous servo motor to 310 V; 610 mm travel range; 500 N load capacity; 300 mm/s maximum velocity; ball screw; absolute rotary encoder, multiturn; electromagnetic holding brake

High-load linear stage; synchronous servo motor to 310 V; 610 mm travel range; 500 N load capacity; 300 mm/s maximum velocity; ball screw; absolute rotary encoder, multiturn; electromagnetic holding brake; folded drivetrain

How to Get a Quote

Ask an engineer!

Quickly receive an answer to your question by email or phone from a local PI sales engineer.

Technology

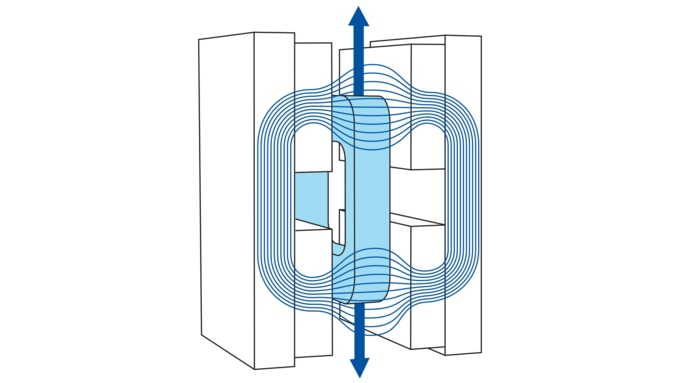

Electromagnetic Drives

Rotating electric motors such as DC or stepper motors are used in connection with screw or worm drives. Stepper motor systems with high-resolution encoders can perform minimum incremental motions of 10 nm with high reliability and repeatability.

Hybrid Concept

In the hybrid concept, the DC servo motor (large travel ranges) and the piezo drive (nanometer accuracy) are combined with one another.

PIMag® 6-D Magnetic Levitation

PIMag® 6-D is an electromagnetic positioning system in which the passive platform levitates on a magnetic field and is actively guided by it.

Magnetic Direct Drives

In particular in terms of wear and dynamics, magnetic direct drives offer advantages compared to common spindle-based technologies.

Rotating Electric Motors

Rotating electric motors such as DC or stepper motors are used in connection with screw or worm drives.