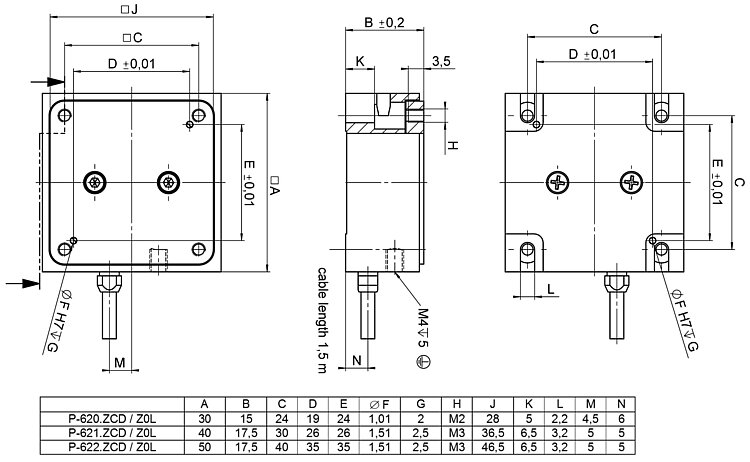

Precise PIHera vertical nanopositioning stage, 65 µm, without sensor, LEMO connectors

P-620.Z - P-622.Z PIHera Vertical Precision Positioner

Variable Travel Ranges and Axis Configuration

- Travel ranges 50 µm to 250 µm (350 µm open loop)

- Resolution to 0.1 nm

- Linearity error only 0.02 %

- Direct position measuring with capacitive sensors

- X, XY, Z, XYZ versions

Application fields

- Interferometry

- Microscopy

- Nanopositioning

- Biotechnology

- Test applications

- Semiconductor technology

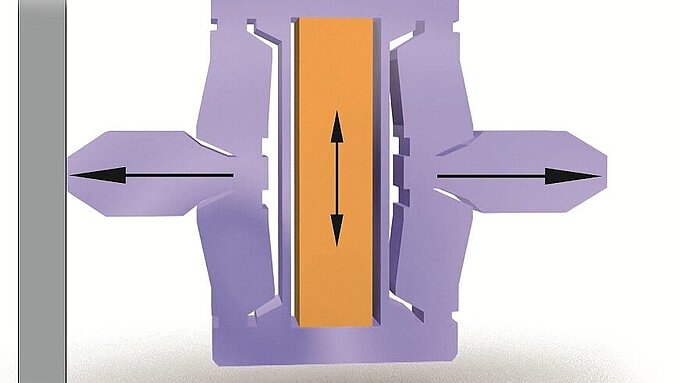

Outstanding lifetime due to PICMA® piezo actuators

The PICMA® piezo actuators are all-ceramic insulated. This protects them against humidity and failure resulting from an increase in leakage current. PICMA® actuators offer an up to ten times longer lifetime than conventional polymer-insulated actuators. 100 billion cycles without a single failure are proven.

Subnanometer resolution with capacitive sensors

Capacitive sensors measure with subnanometer resolution without contacting. They guarantee excellent linearity of motion, long-term stability, and a bandwidth in the kHz range.

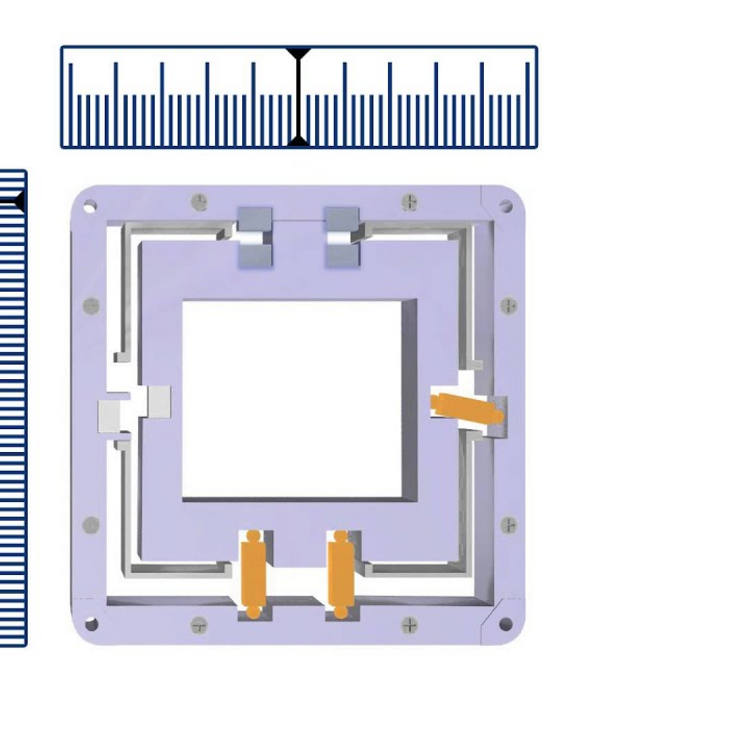

High guiding accuracy due to zero-play flexure guides

Flexure guides are free of maintenance, friction, and wear, and do not require lubrication. Their stiffness allows high load capacity and they are insensitive to shock and vibration. They work in a wide temperature range.

Maximum accuracy due to direct position measuring

Motion is measured directly at the motion platform without any influence from the drive or guide elements. This allows optimal repeatability, outstanding stability, and stiff, fast-responding control.

Specifications

Specifications

| Motion | P-620.Z0L | P-620.ZCD | P-620.ZCL | P-621.Z0L | P-621.ZCD | P-621.ZCL | P-622.Z0L | P-622.ZCD | P-622.ZCL | Tolerance |

|---|---|---|---|---|---|---|---|---|---|---|

| Active axes | Z | Z | Z | Z | Z | Z | Z | Z | Z | |

| Travel range in Z, open loop | 65 µm | 65 µm | 65 µm | 140 µm | 140 µm | 140 µm | 350 µm | 350 µm | 350 µm | ±20 % |

| Yaw (Rotational crosstalk in θX with motion in Z) | ± 80 µrad | ± 80 µrad | ± 80 µrad | ± 100 µrad | ± 100 µrad | ± 100 µrad | ± 200 µrad | ± 200 µrad | ± 200 µrad | typ. |

| Pitch (Rotational crosstalk in θY with motion in Z) | ± 80 µrad | ± 80 µrad | ± 80 µrad | ± 100 µrad | ± 100 µrad | ± 100 µrad | ± 200 µrad | ± 200 µrad | ± 200 µrad | typ. |

| Travel range in Z | 50 µm | 50 µm | 100 µm | 100 µm | 250 µm | 250 µm | ||||

| Linearity error in Z | 0.02 % | 0.02 % | 0.02 % | 0.02 % | 0.02 % | 0.02 % | typ. | |||

| Positioning | P-620.Z0L | P-620.ZCD | P-620.ZCL | P-621.Z0L | P-621.ZCD | P-621.ZCL | P-622.Z0L | P-622.ZCD | P-622.ZCL | Tolerance |

| Resolution in Z, open loop | 0.1 nm | 0.1 nm | 0.1 nm | 0.2 nm | 0.2 nm | 0.2 nm | 0.5 nm | 0.5 nm | 0.5 nm | typ. |

| Bidirectional repeatability in Z | 1 nm | 1 nm | 1 nm | 1 nm | 1 nm | 1 nm | typ. | |||

| Integrated sensor | Capacitive, direct position measuring | Capacitive, direct position measuring | Capacitive, direct position measuring | Capacitive, direct position measuring | Capacitive, direct position measuring | Capacitive, direct position measuring | ||||

| System resolution in Z | 0.2 nm | 0.2 nm | 0.3 nm | 0.3 nm | 1 nm | 1 nm | ||||

| Drive Properties | P-620.Z0L | P-620.ZCD | P-620.ZCL | P-621.Z0L | P-621.ZCD | P-621.ZCL | P-622.Z0L | P-622.ZCD | P-622.ZCL | Tolerance |

| Drive type | PICMA® | PICMA® | PICMA® | PICMA® | PICMA® | PICMA® | PICMA® | PICMA® | PICMA® | |

| Maximum power consumption | 5 W | 5 W | 5 W | 18 W | 18 W | 18 W | 17 W | 17 W | 17 W | |

| Electrical capacitance in Z | 0.7 µF | 0.7 µF | 0.7 µF | 3 µF | 3 µF | 3 µF | 6.2 µF | 6.2 µF | 6.2 µF | ±20 % |

| Short-term maximum operating frequency | 333 Hz | 333 Hz | 333 Hz | 263 Hz | 263 Hz | 263 Hz | 120 Hz | 120 Hz | 120 Hz | |

| Mechanical Properties | P-620.Z0L | P-620.ZCD | P-620.ZCL | P-621.Z0L | P-621.ZCD | P-621.ZCL | P-622.Z0L | P-622.ZCD | P-622.ZCL | Tolerance |

| Stiffness in Z | 0.5 N/µm | 0.5 N/µm | 0.5 N/µm | 0.6 N/µm | 0.6 N/µm | 0.6 N/µm | 0.24 N/µm | 0.24 N/µm | 0.24 N/µm | ±20 % |

| Resonant frequency in Z, unloaded | 1000 Hz | 1000 Hz | 1000 Hz | 790 Hz | 790 Hz | 790 Hz | 360 Hz | 360 Hz | 360 Hz | ±20 % |

| Resonant frequency in Z, under load with 30 g | 690 Hz | 690 Hz | 690 Hz | 500 Hz | 500 Hz | 500 Hz | 270 Hz | 270 Hz | 270 Hz | ±20 % |

| Permissible push force in Y | 10 N | 10 N | 10 N | 10 N | 10 N | 10 N | 10 N | 10 N | 10 N | max. |

| Permissible push force in Z | 10 N | 10 N | 10 N | 10 N | 10 N | 10 N | 10 N | 10 N | 10 N | max. |

| Permissible pull force in Z | 5 N | 5 N | 5 N | 8 N | 8 N | 8 N | 8 N | 8 N | 8 N | max. |

| Guide | Flexure guide with lever amplification | Flexure guide with lever amplification | Flexure guide with lever amplification | Flexure guide with lever amplification | Flexure guide with lever amplification | Flexure guide with lever amplification | Flexure guide with lever amplification | Flexure guide with lever amplification | Flexure guide with lever amplification | |

| Overall mass | 120 g | 120 g | 120 g | 170 g | 170 g | 170 g | 240 g | 240 g | 240 g | |

| Material | Aluminum | Aluminum | Aluminum | Aluminum | Aluminum | Aluminum | Aluminum | Aluminum | Aluminum | |

| Miscellaneous | P-620.Z0L | P-620.ZCD | P-620.ZCL | P-621.Z0L | P-621.ZCD | P-621.ZCL | P-622.Z0L | P-622.ZCD | P-622.ZCL | Tolerance |

| Operating temperature range | -20 to 150 °C | -20 to 80 °C | -20 to 80 °C | -20 to 150 °C | -20 to 80 °C | -20 to 80 °C | -20 to 150 °C | -20 to 80 °C | -20 to 80 °C | |

| Connector | LEMO FFS.00.250.CTCE24 | D-sub 7W2 (m) | LEMO FFS.00.250.CTCE24 | LEMO FFS.00.250.CTCE24 | D-sub 7W2 (m) | LEMO FFS.00.250.CTCE24 | LEMO FFS.00.250.CTCE24 | D-sub 7W2 (m) | LEMO FFS.00.250.CTCE24 | |

| Cable length | 1.5 m | 1.5 m | 1.5 m | 1.5 m | 1.5 m | 1.5 m | 1.5 m | 1.5 m | 1.5 m | |

| Recommended controllers / drivers | E-503, E-505, E-610 | E-503, E-505, E-610, E-621, E-625, E-709.1C1L, E-754 | E-503, E-505, E-610, E-621, E-625, E-709.1C1L, E-754 | E-503, E-505, E-610 | E-503, E-505, E-610, E-621, E-625, E-709.1C1L, E-754 | E-503, E-505, E-610, E-621, E-625, E-709.1C1L, E-754 | E-503, E-505, E-610 | E-503, E-505, E-610, E-621, E-625, E-709.1C1L, E-754 | E-503, E-505, E-610, E-621, E-625, E-709.1C1L, E-754 | |

| Sensor connector | D-sub 7W2 (m) | LEMO for capacitive sensors | D-sub 7W2 (m) | LEMO for capacitive sensors | D-sub 7W2 (m) | LEMO for capacitive sensors |

The resolution of the system is limited only by the noise of the amplifier and the measuring technology because PI piezo nanopositioning systems are free of friction.

All specifications based on room temperature (22 °C ±3 °C).

Downloads

Product Note

Product Change Notification Piezo Actuator Driven Products

Datasheet

Documentation

User Manual PZ234

P-620, P-621, P-622, P-625, P-628, P-629 PIHera Piezo Stages with Capacitive Sensors

3D Models

P-62x.Z 3-D model

Quote / Order

Ask for a free quote on quantities required, prices, and lead times or describe your desired modification.

Precise PIHera vertical nanopositioning stage, 50 µm, direct position measuring, capacitive sensor, D-sub connector

Precise PIHera vertical nanopositioning stage, 50 µm, direct position measuring, capacitive sensor, LEMO connectors

Precise PIHera vertical nanopositioning stage, 140 µm, without sensor, LEMO connectors

Precise PIHera vertical nanopositioning stage, 100 µm, direct position measuring, capacitive sensor, D-sub connector

Precise PIHera vertical nanopositioning stage, 100 µm, direct position measuring, capacitive sensor, LEMO connectors

Precise PIHera vertical nanopositioning stage, 350 µm, without sensor, LEMO connectors

Precise PIHera vertical nanopositioning stage, 250 µm, direct position measuring, capacitive sensor, D-sub connector

Precise PIHera vertical nanopositioning stage, 250 µm, direct position measuring, capacitive sensor, LEMO connectors

Come Ricevere un’Offerta

Chiedi ad un Ingegnere!

Ricevere rapidamente una risposta alla tua risposta via email o telefono da un Sales Engineer dalla sede PI più vicina a te.

Tecnologia

Tecnologia PICMA®

Elevata affidabilità e lunga durata attraverso il processo di produzione brevettato per attuatori multistrato.

Sistemi con Guida a Flessione

Le Guide a Flessione realizzate da PI hanno dimostrato i loro punti di forza nei nanoposizionatori. Guidano l'attuatore piezoelettrico e garantiscono un movimento rettilineo senza inclinazione o spostamento laterale.

Sensori Capacitivi

I sensori capacitivi sono il sistema metrologico prescelto per le applicazioni più esigenti di nanoposizionamento.

Vuoto

Gestione attenta, locali adeguati: PI non solo ha le attrezzature necessarie per la qualificazione dei materiali, dei componenti e dei prodotti finiti, ma vanta anche molti anni di esperienza per quanto riguarda sistemi di posizionamento in HV e UHV.

Technology

Tecnologia PICMA®

Elevata affidabilità e lunga durata attraverso il processo di produzione brevettato per attuatori multistrato.

Sistemi con Guida a Flessione

Le Guide a Flessione realizzate da PI hanno dimostrato i loro punti di forza nei nanoposizionatori. Guidano l'attuatore piezoelettrico e garantiscono un movimento rettilineo senza inclinazione o spostamento laterale.

Sensori Capacitivi

I sensori capacitivi sono il sistema metrologico prescelto per le applicazioni più esigenti di nanoposizionamento.