Piezo Z stage; 120 µm travel range (open loop); LEMO connector; 1.5 m cable length

P-611.Z Piezo Z Stage

Compact Nanopositioner

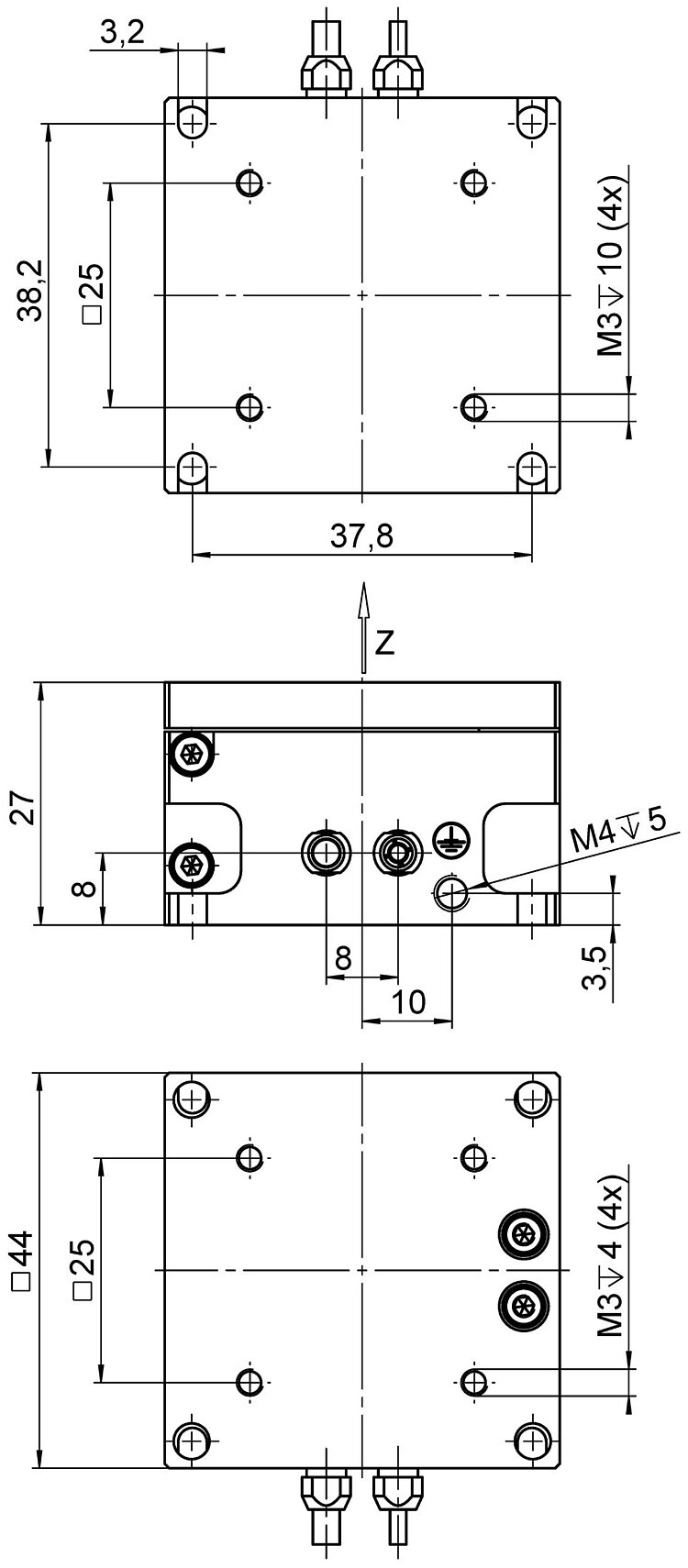

- Compact: Surface only 44 mm × 44 mm

- Travel range 100 µm

- Resolution to 0.2 nm

- Particularly inexpensive systems (mechanics and controller)

- Zero-play, high-precision flexure guide system

- Outstanding lifetime due to PICMA® piezo actuators

- X, XY, XZ and XYZ versions

Application fields

- Micromachining

- Photonics

- Fiber positioning

- Test procedures and quality assurance

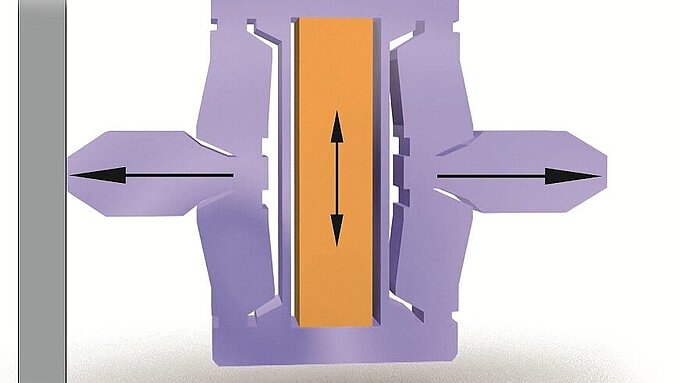

Outstanding lifetime thanks to PICMA® piezo actuators

The PICMA® piezo actuators are all-ceramic insulated. This protects them against humidity and failure resulting from an increase in leakage current. PICMA® actuators offer an up to ten times longer lifetime than conventional polymer-insulated actuators. 100 billion cycles without a single failure are proven.

Specifications

Specifications

| Motion | P-611.Z0 | P-611.ZS | Tolerance |

|---|---|---|---|

| Active axes | Z | Z | |

| Travel range in Z, open loop | 120 µm | 120 µm | ±20 % |

| Yaw (Rotational crosstalk in θX with motion in Z) | ± 20 µrad | ± 20 µrad | typ. |

| Pitch (Rotational crosstalk in θY with motion in Z) | ± 5 µrad | ± 5 µrad | typ. |

| Roll (Rotational crosstalk in θZ with motion in Z) | ± 5 µrad | ± 5 µrad | typ. |

| Bandwidth, 10% step in Z | 40 Hz | 40 Hz | |

| Travel range in Z | 100 µm | ||

| Linearity error in Z | 0.1 % | typ. | |

| Positioning | P-611.Z0 | P-611.ZS | Tolerance |

| Resolution in Z, open loop | 0.2 nm | 0.2 nm | typ. |

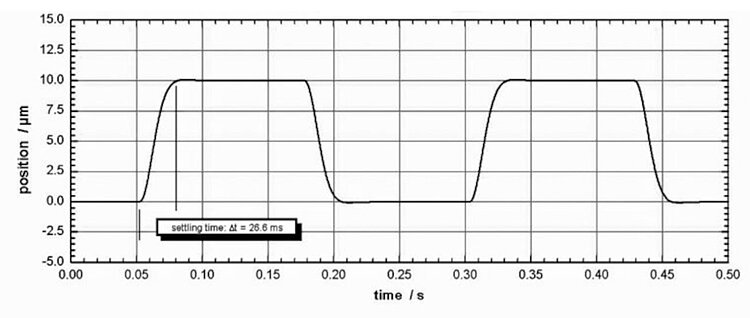

| Settling time for 10% step in Z | 25 ms | 25 ms | |

| Bidirectional repeatability in Z | 5 nm | typ. | |

| Integrated sensor | SGS, indirect position measuring | ||

| System resolution in Z | 2 nm | ||

| Drive Properties | P-611.Z0 | P-611.ZS | Tolerance |

| Drive type | PICMA® | PICMA® | |

| Electrical capacitance in Z | 1.5 µF | 1.5 µF | ±20 % |

| Mechanical Properties | P-611.Z0 | P-611.ZS | Tolerance |

| Stiffness in Z | 0.45 N/µm | 0.45 N/µm | ±20 % |

| Resonant frequency in Z, unloaded | 460 Hz | 460 Hz | ±20 % |

| Resonant frequency in Z, under load with 30 g | 375 Hz | 375 Hz | ±20 % |

| Resonant frequency in Z, under load with 100 g | 265 Hz | 265 Hz | ±20 % |

| Permissible push force in Z | 15 N | 15 N | max. |

| Permissible pull force in Z | 10 N | 10 N | max. |

| Guide | Flexure guide with lever amplification | Flexure guide with lever amplification | |

| Overall mass | 176 g | 176 g | |

| Material | Aluminum, steel | Aluminum, steel | |

| Miscellaneous | P-611.Z0 | P-611.ZS | Tolerance |

| Operating temperature range | -20 to 80 °C | -20 to 80 °C | |

| Connector | LEMO FFS.00.250.CTCE24 | LEMO FFS.00.250.CTCE24 | |

| Cable length | 1.5 m | 1.5 m | |

| Recommended controllers / drivers | E-610, E-625, E-665, E-836 | E-610, E-625, E-665, E-709.SRG, E-836 | |

| Sensor connector | LEMO FFA.0S.304.CLAC32 |

The resolution of the system is limited only by the noise of the amplifier and the measuring technology because PI piezo nanopositioning systems are free of friction.

System properties

System configuration: P-611.ZS and E-665.SR controller with 30 g load

Downloads

Datasheet

Documentation

User Manual PZ253

P-611 Nanopositioning Systems with Strain Gauge Sensors / without Sensor

Unpacking Instructions P611T0006

Unpacking and Handling of P-611 Positioners

3D Models

P-611.Z 3-D model

Quote / Order

Ask for a free quote on quantities required, prices, and lead times or describe your desired modification.

Piezo Z stage; 100 µm travel range; SGS, indirect position measuring; LEMO connectors; 1.5 m cable length

How to Get a Quote

Ask an engineer!

Quickly receive an answer to your question by email or phone from a local PI sales engineer.

Technology

PICMA® Technology

Highly reliable and extended lifetime through the patented manufacturing process for multilayer actuators.

Flexure Guiding Systems

Flexure guides from PI have proven their worth in nanopositioning. They guide the piezo actuator and ensure a straight motion without tilting or lateral offset.