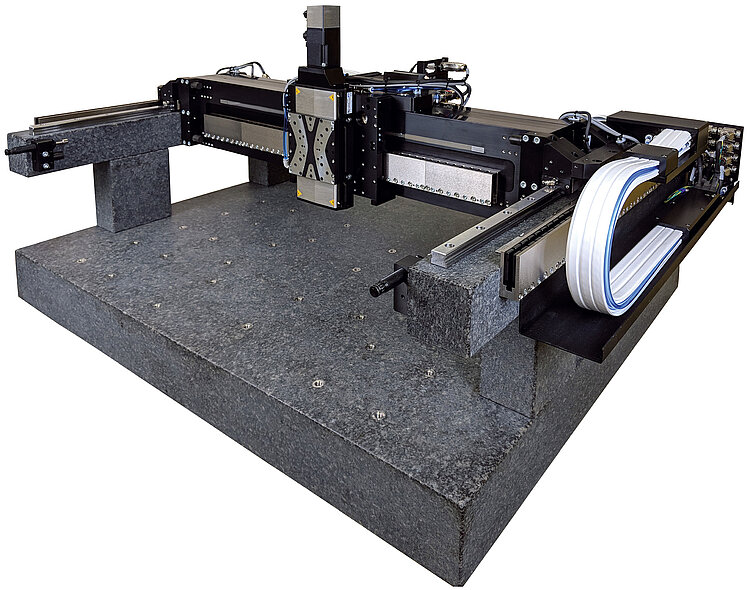

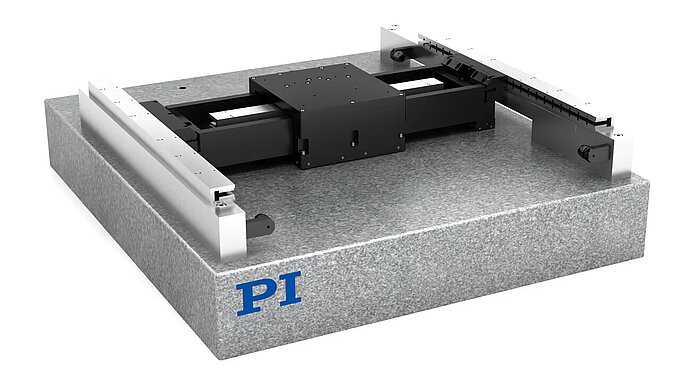

A-341 PIglide HGS Hybrid Gantry System

Hybrid Guide Design with Air Bearings and Recirculating Ball Bearing Guides for High Precision with Low Profile.

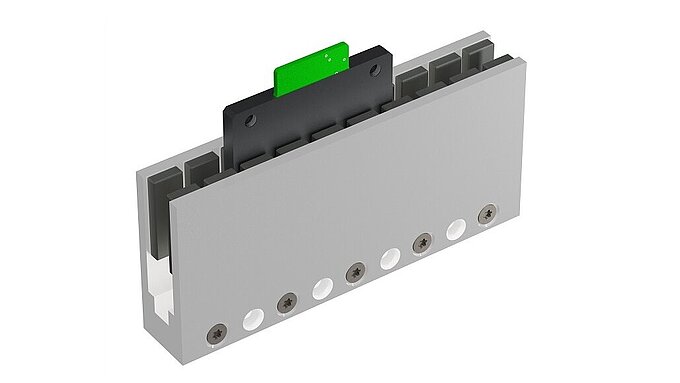

- Hybrid design: Gantry axis with recirculating ball bearing guides, bridge axis with air bearing

- Absolute encoder

- High-performance ironless linear motors

- Various travel ranges. Options and customized adaptations

- Flexible modular platform

Overview

The A-341 PIglide HGS hybrid gantry system was developed for applications that require overhead motion and long travel ranges.

The A-341 hybrid gantry has a unique hybrid guide design. The bridge axis is equipped with a friction-free guide with air bearings that allow exact control of velocity as well as outstanding repeatability and straightness. The guide with air bearings considerably reduces particle emission over the workspace. The gantry axis is equipped with recirculating ball bearing guides on both sides for robustness and precision in limited installation space.

This combination of different guide technologies means that the A-341 hybrid gantry is ideally suited to applications that are based on the step-and-scan principle and at the same time, require a compact design.

The A-341 is coupled with industry-leading controllers and drive modules from ACS that offer superior servo performance, advanced control algorithms to improve dynamic performance and error compensation, and a wide suite of software development tools.

Absolute encoder

Absolute encoders supply explicit position information that enables immediate determination of the position. This means that referencing is not required during switch-on, which increases efficiency and safety during operation.

PIMag® magnetic direct drive

3-phase magnetic direct drives do not use mechanical components in the drivetrain, they transmit the drive force to the motion platform directly and without friction. The drives reach high velocities and accelerations. Ironless motors are particularly suitable for positioning tasks with the highest demands on precision because there is no undesirable interaction with the permanent magnets. This allows smooth running even at the lowest velocities and at the same time, there is no vibration at high velocities. Nonlinearity in control behavior is avoided and any position can be controlled easily. The drive force can be set freely.

Options and customized adaptations

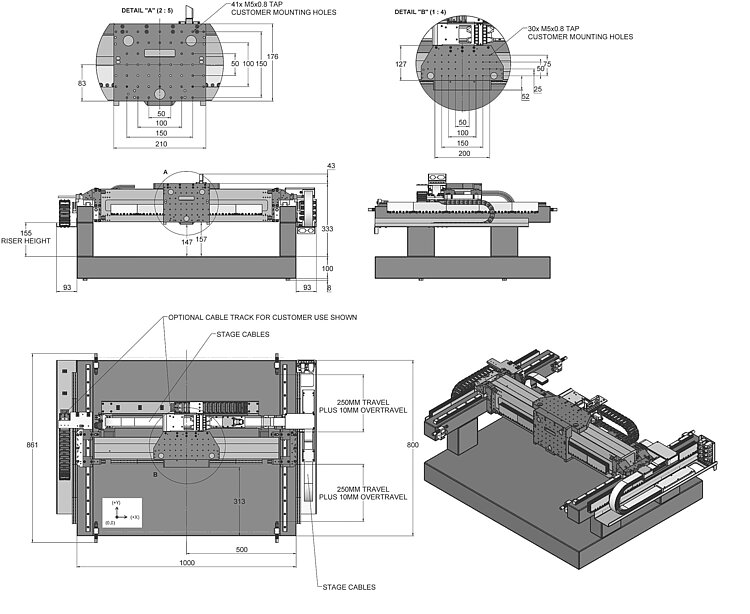

- Base made of granite or aluminum

- Adjustable work height

- Systems for reducing vibration

- Additional drag chains

- Performance of the linear motors

- Liquid cooling of the linear motors

Application fields

Scanning, Digital printing, Electronics assembly and inspection, AOI (Automatic Optical Inspection), Automation.

Specifications

Specifications

Motion | Unit | Bridge axis | Gantry axis |

|---|---|---|---|

Travel range | mm | 300 500 | 300 500 750 1000 |

Guide | Air bearing, pneumatic preloading | Recirculating ball bearing guide | |

Drive | 1 × Ironless 3-phase linear motor | 2 × Ironless 3-phase linear motor | |

Measuring system | Absolute linear encoder, 1 nm sensor resolution, BiSS-C, steel measuring scale | 2 × Absolute linear encoder, 1 nm sensor resolution, BiSS-C, steel measuring scale | |

Load capacity (1) | 10 kg | ||

Positioning accuracy, calibrated (2) | µm | ±0.75 | ±2 |

XY orthogonality | µrad | 25 | |

Max. velocity, unloaded (3) | m/s | 2 | 1 |

Moved mass | kg | 5 | Depending on the travel range of the bridge axis: 300 mm: 25 kg 500 mm: 30 kg |

Miscellaneous | |

|---|---|

Operating pressure | 550 ±35 kPa (80 ±5 psi) |

Air consumption | < 30 l/min (1SCFM) |

Air quality | Clean (filtered to 1.0 μm or better) - ISO 8573‑1 Class 1 Oil free - ISO 8573‑1 Class 1 Dry (-15 °C dew point) - ISO 8573‑1 Class 3 |

Materials | Hardcoat aluminum Guide rails made of steel, cleanroom grease (guide rails made of stainless steel on request) Mounting hardware made of stainless steel |

Recommended controllers | A-81x, A-82x |

Quote / Order

Ask for a free quote on quantities required, prices, and lead times or describe your desired modification.

How to Get a Quote

Ask an engineer!

Quickly receive an answer to your question by email or phone from a local PI sales engineer.