Mr. Wins, for your magnetic linear and rotation stages you rely mainly on strong suppliers from the motor industry. With the Driven by PIMag® brand name you are increasingly strengthening your company's expertise in motor design, construction, and manufacturing. What is the motivation behind it?

With the development of our own technologies we want to set new standards for our customers. We develop solutions swiftly and without a large one-off cost for prototypes and then offer these to our customers. We do this even though it is not yet certain if the series will be produced; ultimately, this is always the goal we want to achieve. With the help of the motors developed in-house, without having to line up along the development pipeline of our suppliers, we can provide customized actuators which have been designed specifically for the requirements of the application.

Does this mean that you become your suppliers' competitor?

No, this is not what PI wants to do. We cannot compete with the standard motors of our suppliers since we do not produce our motors in such large quantities as our suppliers can distribute theirs. The focus of our work is not just the motor, but the entire positioning solution including the motor, the guides, the encoder, the controller, and other components.

When do you particularly often use the motors developed in-house?

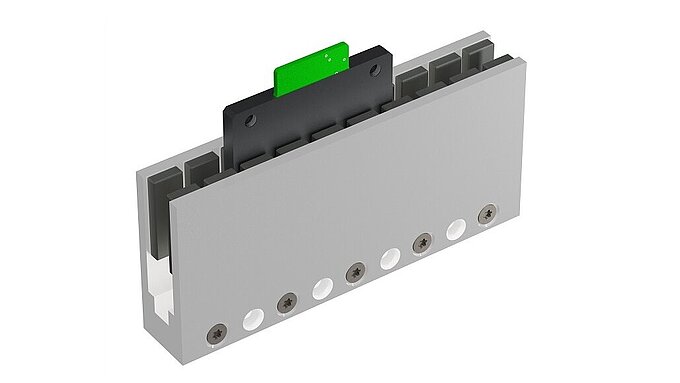

We use our motors when we cannot find the perfect solution required for our customer's applications on the market. This is not only the case with customized solutions. Even some standard series require customized motors, for example, for the particularly flat linear stages of the V-508 series. By strengthening our expertise in the development of motors for magnetic direct drives, we can, in combination with our simulation tools, ultimately provide the ideal solution for our customers. This can for example, be optimized with regard to the force/space ratio.

Which motors do you integrate into your positioning systems?

PI can build voice coil, ironless and iron-core linear motors as well as a variety of torque motors. These can, for example, be designed for particularly compact spaces, particularly high force or motor constants, or even for very high accuracy requirements in precision automation.

And where are they typically used?

Our voice coil motors are, for example, suitable for scanning applications with travel ranges up to a few tens of millimeters. Even solutions with hollow shafts can be realized, for example, for use in medical endoscopes. Our linear motors can be used for significantly larger travel ranges. Iron-core linear motors are suitable for applications requiring high forces and accelerations with limited installation space whereas ironless linear motors are suitable for positioning tasks with very high demands on precision in the smallest installation spaces.

Our torque motors can, for example, be built particularly flat or somewhat deeper if higher torque densities are required. In addition, hollow shafts of different sizes can be realized, for example, to feed through cables, optical beams, or similar things. They are mainly used in rotation stages and are often also stacked onto PI hexapods or XY(Z) setups.

What is the main benefit for the customers when using these motors?

With our motors, we offer the customer a similar depth of technology to our piezoceramic drives. For our precision positioning products we can offer almost everything from a single source, therefore, in comparison to other manufacturers, we can react more independently and flexibly to the customer's requirements. One of the biggest advantages, however, lies in the customized adaptation of the motor – that is, exactly for the respective application. In this way, we not only can offer a highly efficient product in competitive quality, but we can do so at an attractive price. Our OEM customers, therefore, get exactly what they really need.