In Devices for Intensive Medical Care, Piezo Elements Make the Detection of Life-Threatening Air Bubbles Possible

Intensive medical care is an increasingly important area of patient care in hospitals, especially during global medical crises. Viruses and other infections are particularly dangerous for people with pre-existing conditions, e.g., of the kidneys or cardiovascular system. In regards to the treatment and therapy of such illnesses, the requirements for the medical devices used are also constantly increasing. Here, piezo technology offers numerous possibilities for improvement: Piezo ultrasonic transducers, for example, make intensive care devices such as infusion systems more intelligent and make the supervision of vital body functions easier.

In addition to piezoceramics made of PZT (lead zirconate titanate), >> lead-free piezoelectric materials also show positive results in terms of sensory performance.

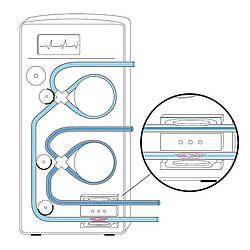

Infusion devices are widely used in intensive care, e.g., in hemodialysis machines for the treatment of chronic kidney diseases. These systems purify the blood of the patient in an extracorporeal cycle in a dialyzer. The diffusion of the toxins takes place between the blood and the dialysate, which is separated by a biocompatible dialysis membrane. In this way, toxins are removed from the blood that would otherwise remain in the bloodstream due to the damage of the kidneys and the resulting impaired detoxification function. After dialysis, the blood is returned to the bloodstream of the patient.

Blood transfusions or the so-called cardiopulmonary bypass, also known as the heart-lung machine, are additional application areas for infusion systems. In lifesaving surgeries, e.g., with an open heart, these systems perform a pumping function of the heart and ensure the oxygen supply of the blood, which is normally ensured by the lung.

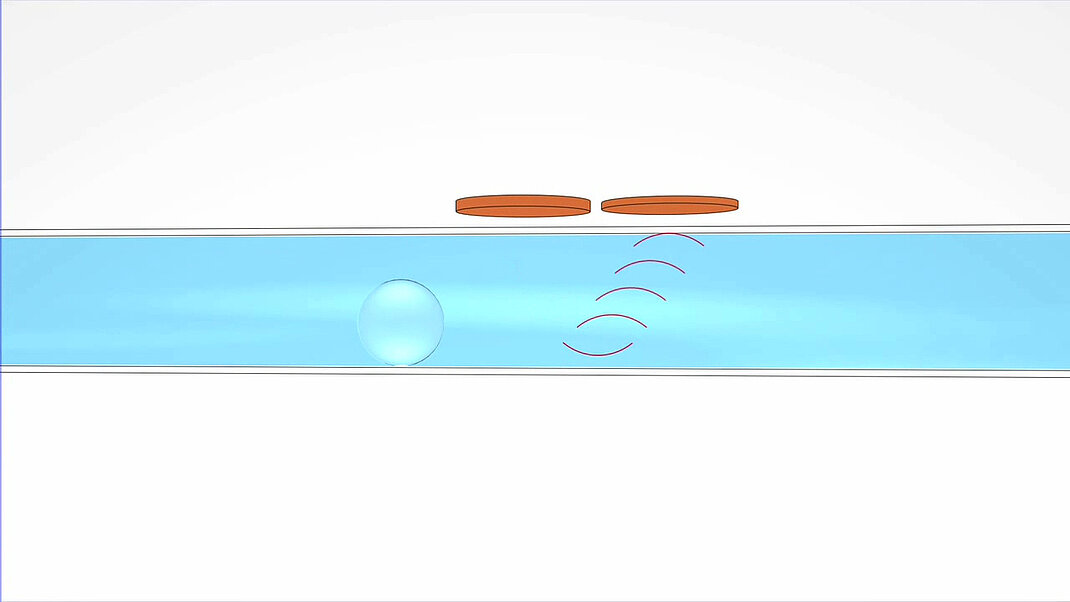

Infusion systems and other medical devices are increasingly using ultrasonic sensors, for example, to measure the blood stream in the tubes or to detect life-threatening air bubbles. Piezo components are particularly suited for this purpose – when they are integrated in ultrasonic sensors they are very compact and can be placed on the outside of the tube. This process is not invasive and counteracts a contamination of the liquid to be monitored by the measuring system.

The piezo plates or disks integrated in the sensors can measure the flow of liquids of a large number of tubes, regardless of the viscosity, thickness, or color of the liquids or tubes. The sensors can also detect air bubbles injected in the bloodstream in real time, so that medical staff can react early on and prevent life-threatening air embolisms. An additional advantage of piezo-driven ultrasonic measurement systems: Because of large series production capabilities, piezo sensors are very cost effective.

The possibility to detect air bubbles increases the safety for the patients immensely. Infusion systems can integrate several air bubble detectors for monitoring. These use the propagation time measurement of the induced sound waves: When sound waves hit an air bubble in a tube, they are reflected at the interface of the bubble since an impedance difference exists between the two media. When comparing the propagation time measurement of an air-bubble-free tube, an air bubble can immediately be detected because of the reduced propagation time of the sound wave. If an air bubble is detected in a tube of, for example, a heart-lung machine, the pumping process is stopped immediately. The contaminated blood is redirected to the reservoir, so that the extracorporeal bloodstream can work again without disruption.

Do you want to know more about our solutions? Our specialists are happy to help.

Contact us today!