Chronic respiratory diseases like mucoviscidosis, asthma or chronic obstructive pulmonary disease (COPD) but also bronchitis, influenza and lung diseases related to COVID-19 require extensive medical treatment. Medical ventilation can be used to save patients’ life improving their clinical condition, during recovery phase or for drug therapy. Medical nebulizers ensure the pulmonary disease therapy by vaporizing drugs so they can be inhaled deeply into the lungs.

Ventilators Must Be Precise and Reliable

Medical ventilator systems ensure regular lung functionality and replace spontaneous breathing for patients with seriously damaged lung functions by means of controlled gas inhalation, exhalation and oxygenation. They are used in case of serious respiratory failure or respiratory deficiency caused by various diseases. These systems are used to accompany anesthesia, during surgeries and in intensive care. When it comes to intensive care with medical ventilation systems, reliability and precision are key. Ultra-responsive automated systems like smart ventilators require highly dynamic elements such as piezo components.

Ventilators provide a mixture of air and oxygen to the patient while ensuring the adequate pressure to ventilate the lungs. Valve functions with flow rates from high to low velocity can be implemented using piezo technology: piezo actuators switch valves directly or work against a closing spring or a flexible tube for volume displacement. Piezoelectric valves can be manufactured in very compact designs with >> PICMA® Multilayer Bending Actuators offering displacements of some millimeters.

Due to their extremely low energy consumption, piezo actuators are ideal for battery-operated portable ventilation devices. The excellent control characteristics of piezo valves using proportional technology allow a very fast and dynamic motion of the valve. As they are very silent in operation, piezo valves are suitable for permanent use even in environments sensitive to noise such as intensive care.

Contactless Flow Measurement with Piezo Transducers

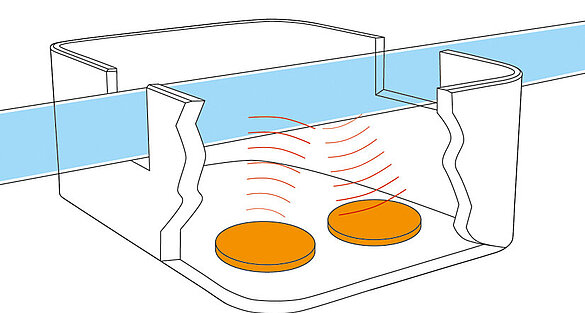

Controlling and monitoring of gas flows are the main tasks in medical ventilators. They enable a continuous air flow, but also detect drops in the flow rate, to adapt the operation of the ventilation system. For run time measuring, piezo components such as discs or plates can be used in ultrasonic transducers to reliably determine gas flow velocity and flow rate. They furthermore allow contactless monitoring of liquids from outside the fluid chambers, which makes them specifically suited for use in medical devices as it prevents contamination. Ultrasonic flow sensors are used in ventilator systems, within the stationary device as well as in respiratory mask itself – depending on the design.

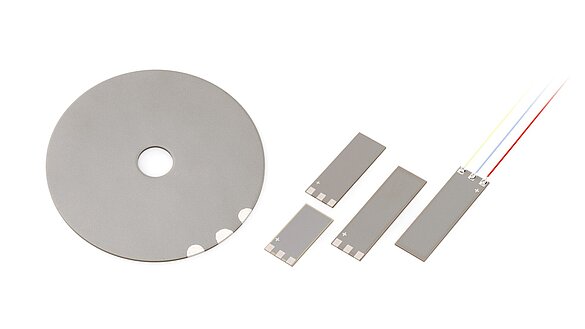

The therapeutic treatment of respiratory diseases traditionally requires drugs to be administered via jet nebulizers. In these devices, the inhalation solution is compressed into very fine droplets. Another solution would be generating droplets using piezo technology in membrane nebulizers with >> piezo rings, discs or plates acting as ultrasonic transducers. They excite a stainless steel membrane with several thousands of micrometer sized holes to high-frequency vibrations and produce particularly homogeneous aerosols. Their compact design and flexible movement modes allow for high forces, accelerations and ultrasonic operating frequencies.

Membrane Nebulizers: Efficient Aerosol Generation with Piezos

Piezo-operated aerosol generation ensures that high-quality drugs are applied in a more targeted manner, opening up innovative therapy concepts and significantly reducing the risk of side effects. As piezo ceramics use a crystal effect to generate displacement, they exhibit neither friction nor wear and therefore don’t require maintenance. Another benefit of piezoelectric aerosol generators is that they are suitable for professional cleaning. Most importantly for patients, membrane nebulizers require far less time to nebulize drugs than conventional systems. In operation, they are almost inaudible and with minimal energy required, the piezo components are highly suitable for portable inhalation devices. This significantly increases the quality of life, especially for patients with chronic respiratory diseases having to inhale frequently.

More Than Just Piezo Ceramics: Assembling Technology by PI Ceramic

Whether it is integrating piezos into ultrasonic transducers or glueing piezos to membranes or diaphragms, PI Ceramic can do more for you than just manufacturing piezo elements. With our profound know-how in testing and packaging, we also support customers in >> glueing or contacting piezo components, as well as in assembling even entire transducers.