Precision positioning of medium loads plays an important role for applications in industry and research. While the use of direct-drive solutions with linear and torque motors is increasing, stages with rotating stepper or DC motor and drive screw are superior to direct drive linear motors particularly for vertical positioning or when it is necessary to achieve high holding forces – when applied to rotary motion, this is also the same for worm drives.

When you consider the variety of mechanical components in such a system, it then becomes an ambitious undertaking to achieve micrometer accuracy and prevent the costs of such stages from going out of all proportion.

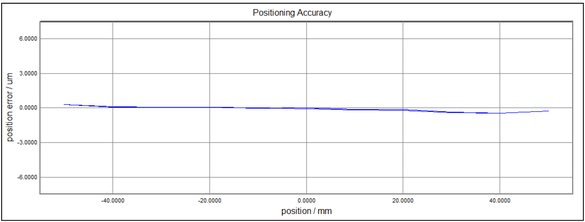

PI miCos knows how to harmonize the components to a precision system. Recirculating ball bearings and crossed roller guides ensure the high load capacity and travel accuracy. Depending on the requirements, direct-measuring encoders are used that do not measure the position by means of the motor shaft rotation but directly at the motion platform. These encoders then have a resolution in a range of up to 1 nanometer and therefore help the controller to achieve a position accuracy of < 1 µm.